How to Classify the Commonly Used E-liquid Flavor?

September 7, 2021

Difference between cotton coil and ceramic core

September 22, 2021As an emerging tobacco consumer product, e-cigarette has gained considerable consumer groups and industrial scale after several years of development. However, as channel layout takes shape, policy supervision becomes stricter, and investment capital increases, the industry has entered a new state of development, and the most profitable stage has passed. In the future, enterprises will compete more in product research and development, manufacturing, brand operation and other skills

The new normal of industrial development, technology will determine the core competitiveness. At present, the main atomization method used in e-cigarettes is heating atomization. Through heating, the liquid is converted into steam, which is further condensed into small droplets and mixed with air to become aerosols.

Heating atomization has always been the main line of atomization core development. During the product iteration, the main focus is to increase safety, promote the use of comfort, and strengthen the machinability of atomization core by changing materials ,improving structure and other ways. So far, the materials used to heat the atomizing core have gone through about three generations of development:

The earliest e-cigarette liquid conduction material is glass fiber rope, whose high temperature resistance solves the problem of dry burning of cotton core. Also glass fiber liquid absorption and liquid conduction performance is also more excellent.

However, there is a major safety hazard in glass fiber rope, when it does not absorb liquid static exposure, easy to produce floccule. Fiberglass cords were phased out of mainstream devices in China between 2014 and 2015, as many e-cigarette users were worried about “powder falling” into their lungs.

Cotton core has the advantage of large liquid storage, good liquid conductivity, rich and real smoke taste. Disadvantages are short life, easy dry burning, taste stability is not enough. Cotton-core technology is a widely used solution, used in big Smoke and JUUL e-cigarette products.

As a common commodity, cotton source is wide, fiber strength is high, if used to prepare atomized core does not need too much processing, the cost is cheaper than ceramic core. The cotton core itself made of cotton is composed of many cotton fibers cross, with a very rich pore structure, and its molecular structure contains hydroxyl so that it has good water absorption, cotton fiber and e-juice contact is very sufficient, so the liquid conduction and atomization effect is good .

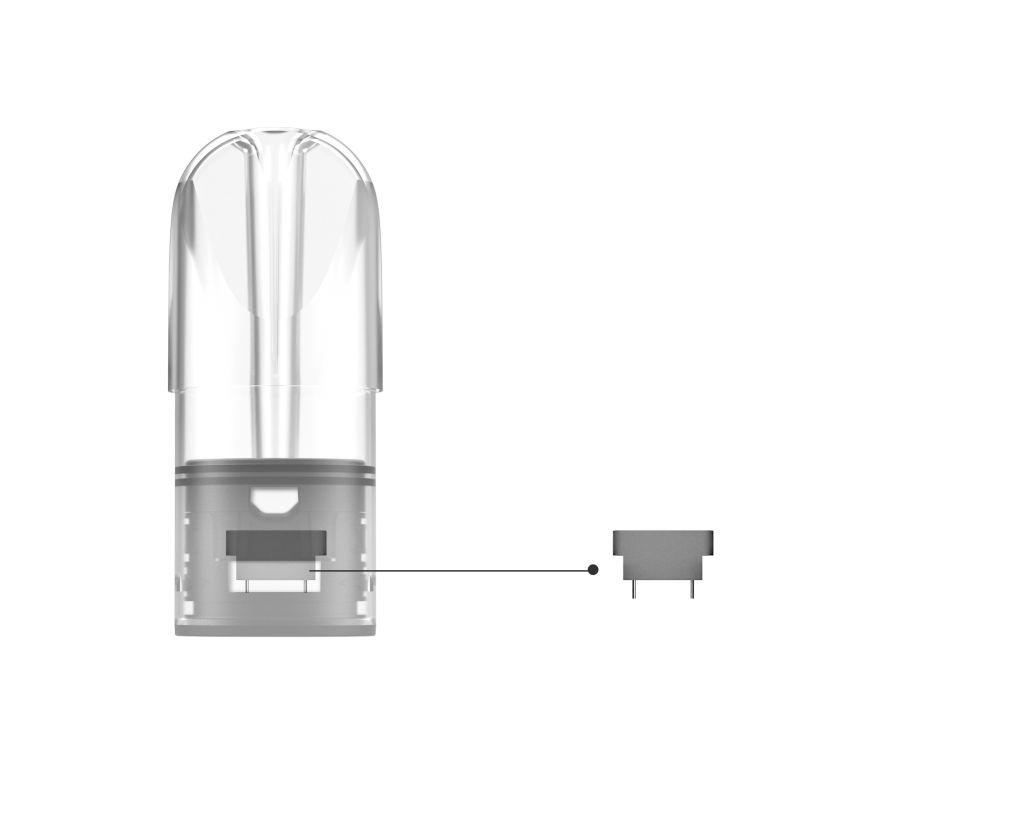

Ceramic core is currently the mainstream of small smoke atomization core materia.

In terms of use experience, the ceramic core is more delicate than the cotton core, and the smoke is more smooth. And the ceramic core stable and durable characteristics, but also to solve the cotton core such as easy dry burning, taste is not stable, easy to paste core and other problems, the basic can achieve atomization taste from the beginning to the end. In terms of production and use efficiency, the ceramic core can be produced into a variety of standard shapes, easy to mass production and assembly. E-cigarette users can also reduce the trouble of making their own atomizing core .